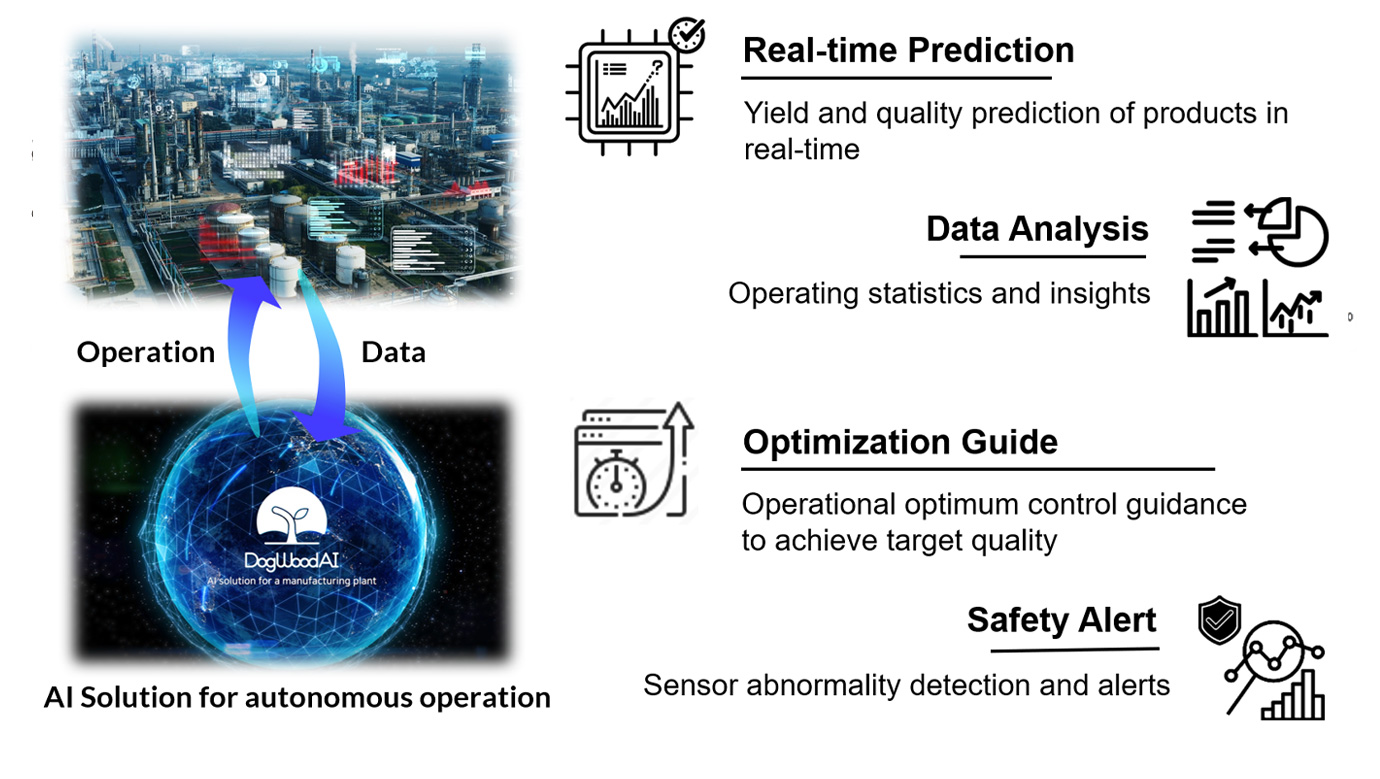

Tailor-made AI solution for a hydrocracking plant in a refinery company

Challenge

Refinery companies require highly accurate, real-time predictions of product yield and quality in complex hydrocracking processes to optimize operations and reduce variability.

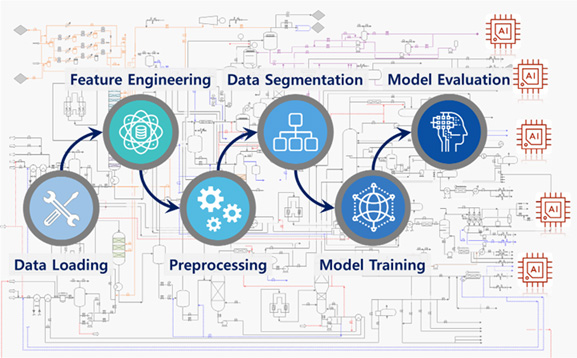

Approach

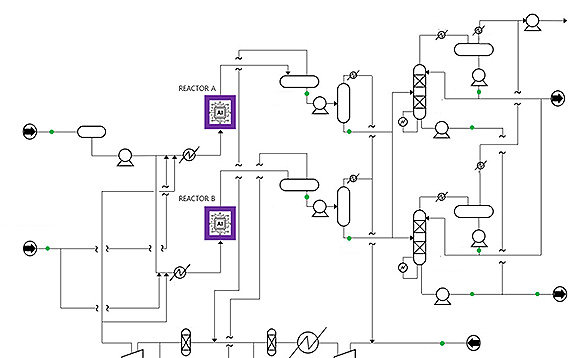

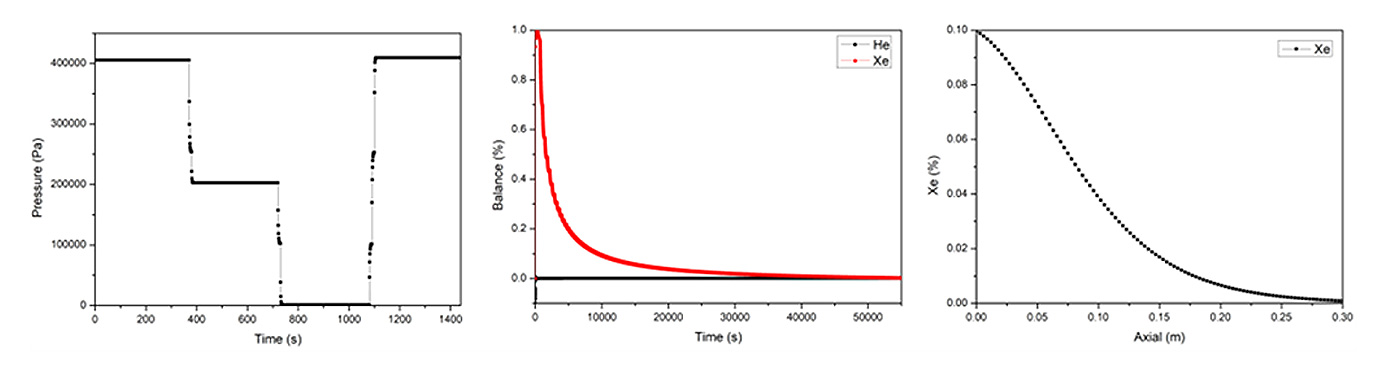

DogWoodAI developed tailored-made AI model designed specifically for hydrocracking plants. The model was built to predict product properties within 1% error and was implemented in close collaboration with the client to ensure continuous field monitoring and improvement.

Value Delivered

The solution was validated over a six-month field test in a Korean refinery. It demonstrated highly accurate, real-time prediction performance, leading to improved process control and decision-making capabilities in a mission-critical environment.