DogwoodAI applies the most suitable machine learning technologies tailored to each client’s needs and plant conditions, developing AI solutions through a range of foundational approaches described below, that support the realization of autonomous manufacturing.

Tailor-made AI Technology

About

Our tailor-made AI technology is specifically developed to address the unique needs of clients under the domain understandings of client data in the industrial sector. It is optimized to utilize real-time data from a wide range of sensors (RTDB) installed in chemical plants.

Features

- Processes and analyzes large volumes of field-generated data

- Predicts multiple product qualities simultaneously

- Customizable for different industrial applications

Benefits

- Enables precise predictions tailored to the specific production environments of manufacturing, refining, and chemical plants

- Improves operational efficiency by utilizing actual plant data

- Enhances product quality and consistency

Case

Korean oil & fine chemical companies successfully completed a 3-6 months field test, validating the solution’s reliability in a real operational environment.

UI Platform for Tailor-made ML for HCR

Real data-based AI Technology

About

This technology focuses on analyzing real-time operational data collected directly from manufacturing plants to provide immediate, actionable insights.

Features

- Monitors and analyzes real-time sensor data

- Predicts key process variables such as product yield and quality

- Outperforms traditional platform-based AI in industrial environments

Benefits

- Provides higher prediction accuracy using actual data

- Supports real-time process control and optimization

- Enhances safety and productivity in manufacturing settings

Model-driven AI Technology

About

Model-based AI leverages first-principle mathematical equations to simulate industrial processes and generate high-quality data for training AI models.

Features

- Creates dynamic models based on governing equations

- Generates synthetic data and conducts sensitivity analyses

- Validates models using real-world measurements

Benefits

- Enables AI development in data-scarce environments

- Reduces dependency on large-scale historical datasets

- Offers scalable modeling for complex integrated processes

Case

Successfully developed and validated a dynamic AI model for an integrated hydrogen production process, enabling efficient hydrogen recovery and CO₂ capture from steam methane reforming tail gas.

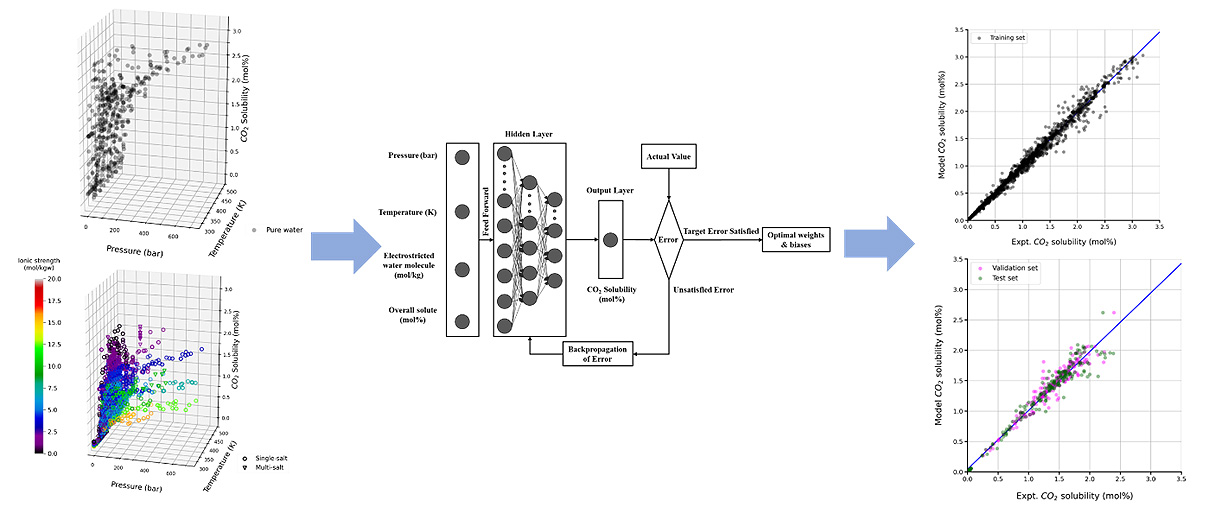

Physics-driven AI Technology

About

Physics-based AI technology combines scientific theory with AI, especially in cases where field data is insufficient for traditional data- based approaches.

Features

- Integrates physicochemical theory with big data AI algorithms

- Predicts beyond actual operating ranges

- Generates consistent, theoretically grounded data

Benefits

- Enables solution development in data-limited industrial environments

- Supports future performance forecasting with enhanced reliability

- Reduces risks associated with data insufficiency

Prediction of solubility in electrochemical solutions through Physics-based ML Solution